High Quality

Optical, Technical and Crystal

Micro-particels (flakes, beads fibres)

Forming technologies to provide glass particles for high-performance composite materials has become a speciality niche for füller. Applications comprise micro-particles like beads (micro-beads but also on mm dia.), flakes, frit, nuggets as well as interface systems for fibre bushing systems.

The segmented, platinum-based stream-feeding system, flow-measuring as well as micro-melting and mini-melting systems provide the melting and feeding infrastructure to melt, feed and form speciality glasses and micro-particles like:

- beads and spheres

- flakes and frit

- nugget for re-melt

Platinum feeding and cutting wheel system

the cutting wheel features all servo-based adjustments of the cutting rotation speed as well as a precise servo-based positioning in the drop point; burner systems and infrared channel equally dispose of servo-based hight and angle adjustment and electronic burner control and all-computer-based temperature controls

Platinum feeding and roller system

the roller system features all servo-based adjustments of the roller rotation as well as press force to maintain the gap set-point as well as a precise servo-based positioning in the drop point and all-computer-based flow control of the cooling water in combination with a temperature feed-back

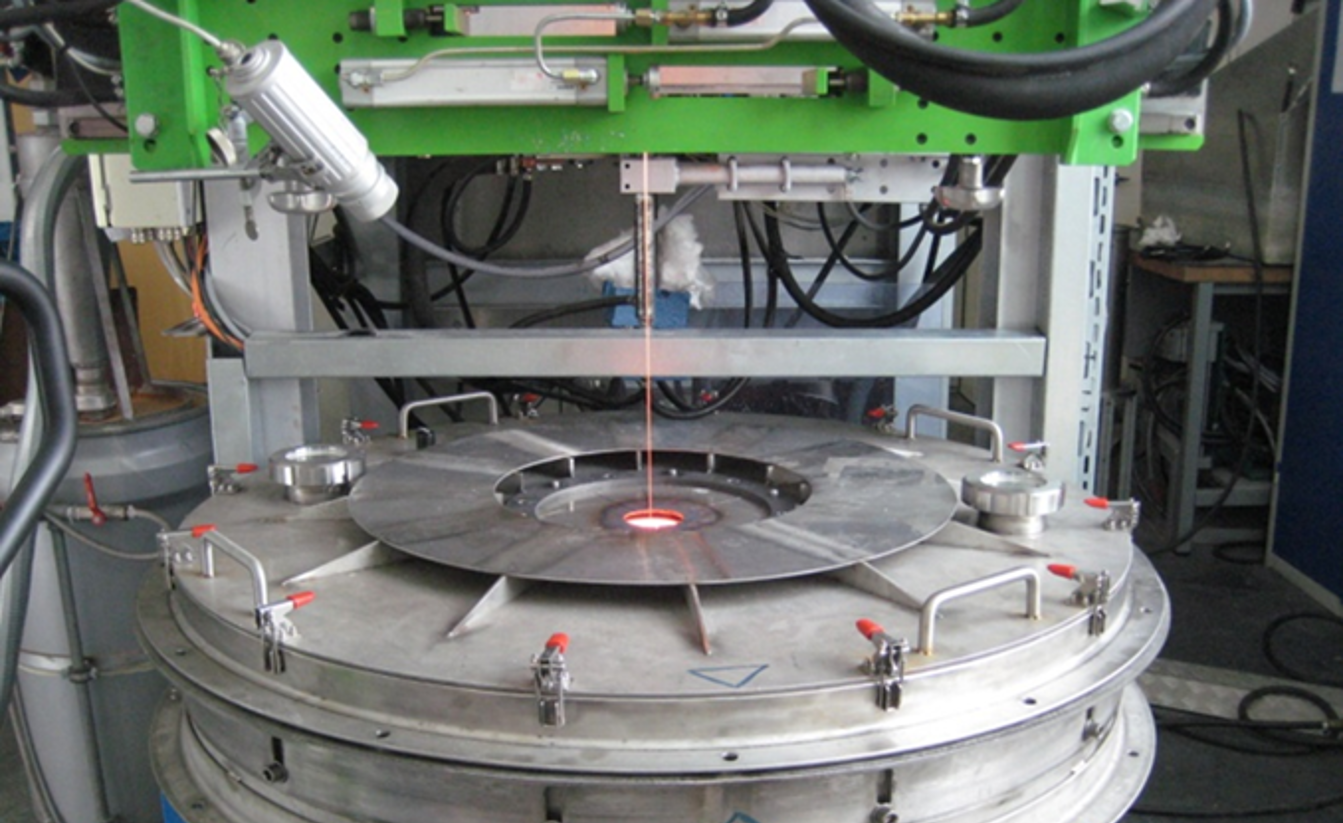

Micro-melter and flaker

the flaker system features all servo-based adjustments of the cup rotation and electronic adjustment of the cup-temperature as well as a precise servo-based positioning in the drop point

Combined with

- mini-melterand micro-melter

- segmented, directly heated platinum feeding system

- flow measuring system (diameter and temperature) and flow temperature control loop

- shear unit

- … and certainly the MMC control

Specification Key Words

- electronic control of all process parameters

- looping-in on glass flow parameters to provide stable conditions for the subsequent processes

- mini-melterand micro-melter

- segmented, directly heated platinum feeding system

- flow measuring system (diameter and temperature) and flow temperature control loop

- shear unit

- … and certainly the MMC control

- electronic control of all process parameters

- looping-in on glass flow parameters to provide stable conditions for the subsequent processes