High Quality

Optical, Technical and Crystal

Blowing (Rotation-Blowing and Stemware)

füller-blowing technologies have become a field with a multitude of technology solutions which may be combined in the most versatile way to meet the production targets in the best way. Applications range from blowing massive containers (see heavy), luxurious decanters, eccentric flacons, ultra-thin and strengthened bottles (see narrow-neck), technical blown and strengthened glass applications as well as smart whiskey tumbler, impressive wine decanters -and of course very delicate stemware – fully integrated with stem pressing and handling as well as stem-welding and -stretching technologies.

Highly instrumented rotation blowing system

- a parison forming system which allows to stretch the limit to flat parisons for thin-walled production and homogeneous wall-thickness distribution targets as well as close-to final shape pre-forming for an active wall thickness distribution control of bottom ice and other design features

- a blowing technology which provides way more than a controlled blow-air impulse but also monitors, controls and optimized the conditioning process prior to blowing

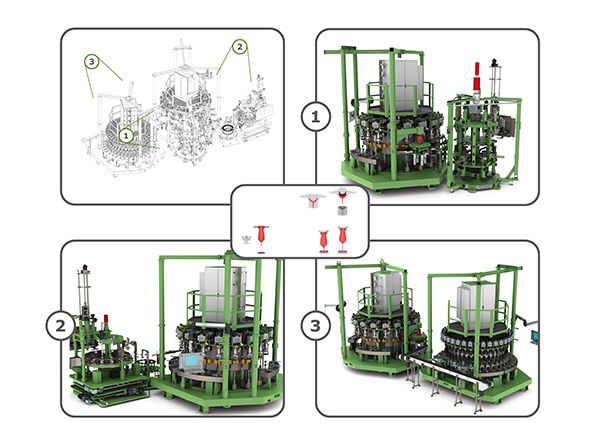

Fully integrated stem-ware line

a modular system which allows to combine single-station parison-forming with single-station as well as 3 and 6 station blowing rotary systems; but also to combine 3, 4 or 6 station parison forming rotary systems with 12, 18 or 24 station rotary systems – or any other combination which provides optimum conditions for synchronized cycles times.

Combined with

- füller-Feeder and shears

- (oscillating) satellite stations for conditioning, in process-welding etc.

- stem-pressing, flame-polishing and handling

- stem-welding and stretching

- strengthening technology

- … and certainly the MMC control

Specification Key Words

- direct feeding – and an integral symbiosis of feeding and parison-forming

- all-servo pre-forming of parison, precise tooling alignment and temperature control

- consistent electronic control for conditioning and blowing – motions, blow-air, temperature as well as flame-control

- integrated safety functions: safe while accessible

- füller-Feeder and shears

- (oscillating) satellite stations for conditioning, in process-welding etc.

- stem-pressing, flame-polishing and handling

- stem-welding and stretching

- strengthening technology

- … and certainly the MMC control

- direct feeding – and an integral symbiosis of feeding and parison-forming

- all-servo pre-forming of parison, precise tooling alignment and temperature control

- consistent electronic control for conditioning and blowing – motions, blow-air, temperature as well as flame-control

- integrated safety functions: safe while accessible